1, Qiimaha Hydroxyl: 1 gram polymer polyol ka kooban hydroxyl (-OH) oo u dhiganta tirada milligaraamyada KOH, unugga mgKOH/g.

2, U dhiganta: celceliska miisaanka kelli ee koox shaqaynaysa.

3, Isocyanate content: content isocyanate in molecule

4, Isocyanate index: waxay muujinaysaa heerka xad-dhaafka isocyanate ee caanaha poliurethane, oo badanaa lagu matalo xarafka R.

5. Silsilad fidiyaha: Waxa ay tilmaamaysaa alkolada iyo aminyada miisaankoodu hooseeyo kuwaas oo fidin kara, balaadhin kara ama samayn kara isku xidhka shabakadaha silsiladaha molecular.

6. Qaybta adag: Qaybta silsiladda oo ay samaysay fal-celinta isocyanate, silsilad fidiyaha iyo crosslinker ee silsiladda ugu weyn ee molecules polyurethane, kooxahani waxay leeyihiin tamar isku-duubni oo weyn, mugga bannaan ee weyn iyo adkeyn weyn.

7, Qaybta jilicsan: kaarboonka silsiladda ugu weyn ee polymer polyol, dabacsanaantu waa wanaagsan tahay, silsiladda ugu weyn ee polyurethane ee qaybta silsiladda dabacsan.

8, Habka hal-tallaabo: waxaa loola jeedaa oligomer polyol, diisocyanate, silsilad fidiyaha iyo kicinta isku dhafan isku mar ka dib duritaanka tooska ah ee caaryada, hab heerkul gaar ah oo lagu daaweynayo qaabaynta.

9, Habka Prepolymer: First oligomer polyol iyo diisocyanate falcelinta prepolymerization, si ay u abuuraan dhamaadka NCO ku salaysan polyurethane prepolymer, shubtay ka dibna falcelinta prepolymer la silsilad fidsan, diyaarinta habka elastomer polyurethane, loo yaqaan prepolymer habka.

10, Habka Semi-prepolymer: farqiga u dhexeeya habka semi-prepolymer iyo habka prepolymer waa in qayb ka mid ah polyester polyol ama polyether polyol lagu daro prepolymer ah qaab isku dar ah oo leh silsilad fidiyaha, kicinta, iwm.

11, Qaabaynta duritaanka falcelinta: Sidoo kale loo yaqaanno Reaction Injection Molding RIM (Reaction Injection Molding), waxaa lagu qiyaasaa oligomers oo leh miisaan yar oo kelli ah oo qaab dareere ah, isla markiiba isku qasan oo lagu duraa caaryada isku mar, iyo falcelinta degdega ah ee dalool caaryada, miisaanka molecular ee maaddadu si degdeg ah ayay u kordheysaa. Nidaam lagu soo saarayo gebi ahaanba polymers cusub oo leh qaab-dhismeedyo kooxeed sifo cusub oo xawaare aad u sarreeya leh.

12, Index xumbo: taas oo ah, tirada qaybaha biyaha ee loo isticmaalo 100 qaybood oo polyeter ah waxaa lagu qeexaa sida xumbo index (IF).

13, Falcelinta xumbo: guud ahaan waxa loola jeedaa falcelinta biyaha iyo isocyanate si ay u soo saaraan urea beddelan oo la sii daayo CO2.

14, Gel reaction: guud ahaan waxa loola jeedaa samaynta falcelinta karbamate.

15, Gel time: xaaladaha qaarkood, walxaha dareeraha ah si ay u sameeyaan jel waqti loo baahan yahay.

16, Waqtiga caanaha: dhamaadka aagga I, ifafaale caano ayaa ka muuqda wajiga dareeraha ee polyurethane. Waqtigaan waxaa lagu magacaabaa wakhtiga kareemka ee jiilka xumbo polyurethane.

17, Isku-xidhka ballaarinta silsiladda: waxaa loola jeedaa saamiga qaddarka amino iyo kooxaha hydroxyl (cutub: mo1) ee qaybaha silsiladaha fidiyaha (oo ay ku jiraan silsiladaha isku dhafan) ilaa qadarka NCO ee prepolymer, taas oo ah, lambarka mole (lambar u dhiganta) saamiga kooxda hydrogen ee firfircoon ilaa NCO.

18, Polyether-ka hooseeya ee hooseeya: inta badan horumarinta PTMG, qiimaha PPG, unsaturation ayaa hoos loo dhigay 0.05mol / kg, oo ku dhow waxqabadka PTMG, iyadoo la adeegsanayo kicinta DMC, noocyada ugu muhiimsan ee alaabta taxanaha Bayer Acclaim.

19, Ammonia ester grade dareeraha: soosaarka dareeraha polyurethane si loo tixgeliyo xoogga kala dirida, heerka isbeddelka, laakiin wax soo saarka poliurethane ee loo isticmaalo dareeraha, waa in ay diiradda saaraan qaadashada NC0 culus ee polyurethane. Xalalka sida aalkolada iyo aalkolada etherka ee ka falceliya kooxaha NCO lama dooran karo. Qalabku kuma jiri karo wasakh sida biyaha iyo khamriga, mana ku jiri karo walxaha alkali, taas oo ka dhigaysa polyurethane sii xumaanaysa.

Walxaha ester-ka looma oggola inuu ku jiro biyo, waana inuusan ku jirin asiidh iyo aalkolo bilaash ah, kuwaas oo ka falcelin doona kooxaha NCO. Walxaha ester-ka ee loo isticmaalo polyurethane waa inuu ahaadaa "ammooniya ester grade dareeraha" oo leh daahir sare. Taasi waa, dareeruhu wuxuu ka falceliyaa isocyanate xad-dhaaf ah, ka dibna qaddarka isocyanate aan la falgelin ayaa lagu go'aamiyaa dibutylamine si loo tijaabiyo inay ku habboon tahay isticmaalka. Mabda'a ayaa ah in isticmaalka isocyanate aan lagu dabaqi karin, sababtoo ah waxay muujinaysaa in biyaha ester-ka, khamriga, acid saddex ay cuni doonaan wadarta qiimaha isocyanate, haddii tirada garaamyada dareeraha loo baahan yahay si loo isticmaalo kooxda leqNCO ayaa la muujiyay, qiimaha waa xasillooni wanaagsan.

Isocyanate oo u dhiganta in ka yar 2500 looma isticmaalo sida dareeraha polyurethane.

Kala duwanaanta dareeraha ayaa saameyn weyn ku leh falcelinta samaynta resinka. Marka uu bato polarity-ka, falcelinta gaabiska, sida toluene iyo methyl ethyl ketone faraqa 24 jeer, polarity molecule molecule waa weyn yahay, wuxuu samayn karaa bond hydrogen ah kooxda hydroxyl aalkolada iyo samaynta falcelinta gaabis ah.

Dareeraha ester-ka ee Polychlorinated ayaa ka fiican in la doorto dareeraha udgoonka, xawaarahooda falcelintu way ka dhakhso badan tahay ester, ketone, sida xylene. Isticmaalka dareeraha ester iyo ketone waxay kordhin karaan nolosha adeegga polyurethane laba-labo ah inta lagu jiro dhismaha. Soo saarista lakabyada, xulashada "qalalka ammonia-grade" ee hore loo sheegay ayaa faa'iido u leh xasiliyeyaasha kaydsan.

Qallalka Ester-ku waxay leeyihiin milmayn xooggan, heerka isbedbedelka dhexdhexaadka ah, suntan hoose oo la isticmaalo in ka badan, cyclohexanone ayaa sidoo kale loo isticmaalaa in ka badan, dareerayaasha hydrocarbon waxay leeyihiin awood hoose oo adag oo adag, isticmaalka yar oo keliya, iyo isticmaalka dheeraadka ah ee dareerayaasha kale.

20, Wakiilka afuufista jirka: wakiilka afuufista jireed waa daloolada xumbo waxay ku sameysmaan isbeddelka qaabka jireed ee walaxda, taas oo ah, iyada oo loo marayo ballaarinta gaaska ciriiriga ah, isbeddelka dareeraha ama kala dirida adkaha.

21, Kiimikada afuufida walxaha: walxaha kiimikaad ah waa kuwa sii dayn kara gaasaska sida carbon dioxide iyo nitrogen ka dib marka la kululeeyo, oo sameeya daloolo yaryar oo ka kooban halabuurka polymer ee xarunta.

22, Isku xidhka jirka: waxaa jira silsilado adag oo ku jira silsilada jilicsan ee polymer, silsiladda adagna waxay leedahay sifooyin jireed oo la mid ah caagga vulcanized ka dib markii kiimikaad isku xirto heerkulka ka hooseeya barta jilicsan ama barta dhalaalka.

23, Kiimikada isku xirka: waxaa loola jeedaa habka isku xirka silsiladaha molecular ee waaweyn iyada oo loo marayo curaarta kiimikada hoos yimaada ficilka iftiinka, kulaylka, shucaaca tamarta sare, xoogga farsamada, ultrasound iyo wakiilada iskutallaabta si loo sameeyo shabakad ama qaab dhismeedka polymer.

24, Tusmada Xumbo-samaynta: tirada qaybaha biyaha oo u dhiganta 100 qaybood oo polyeter ah waxa lagu qeexaa tusaha xumboynta (IF).

25. Waa maxay noocyada isocyyanates ee sida caadiga ah loo isticmaalo marka loo eego qaab-dhismeedka?

A: Aliphatic: HDI, alicyclic: IPDI,HTDI,HMDI, aromatic: TDI,MDI,PAPI,PPDI,NDI.

26. Waa maxay noocyada isocyanates ee badanaa la isticmaalo? Qor qaacidada qaabdhismeedka

A: Toluene diisocyanate (TDI), diphenylmethane-4,4 '-diisocyanate (MDI), polyphenylmethane polyisocyanate (PAPI), liquefied MDI, hexamethylene-diisocyanate (HDI).

27. Macnaha TDI-100 iyo TDI-80?

A: TDI-100 waxay ka kooban tahay toluene diisocyanate oo leh qaab dhismeedka 2,4; TDI-80 waxaa loola jeedaa isku dhafka ka kooban 80% toluene diisocyanate ee qaab dhismeedka 2,4 iyo 20% ee qaab dhismeedka 2,6.

28. Waa maxay sifooyinka TDI iyo MDI ee isku dhafka walxaha polyurethane?

A: Falcelinta 2,4-TDI iyo 2,6-TDI. Dareen-celinta 2,4-TDI waa dhowr jeer ka sarreeya kan 2,6-TDI, sababtoo ah 4-booska NCO ee 2,4-TDI ayaa ka fog 2-booska NCO iyo methyl, waxaana jira ku dhawaad. ma jirto iska caabin adag, halka NCO ee 2,6-TDI ay saameynayso saameynta steric ee kooxda ortho-methyl.

Labada kooxood ee NCO ee MDI aad bay u kala fog yihiin oo ma jiraan wax beddela oo ku hareeraysan, sidaas darteed dhaqdhaqaaqa labada NCO waa mid aad u ballaaran. Xitaa haddii mid ka mid ah NCO uu ka qaybqaato falcelinta, waxqabadka NCO ee haray waa la dhimay, hawshuna weli waa mid aad u weyn guud ahaan. Sidaa darteed, falcelinta MDI polyurethane prepolymer way ka weyn tahay ta TDI prepolymer.

29.HDI, IPDI, MDI, TDI, NDI kee ka mid ah caabbinta jaalaha ah ayaa ka wanaagsan?

A: HDI (waxaa iska leh diisocyanate huruud ah oo aan kala sooc lahayn), IPDI (oo laga sameeyay resin polyurethane leh xasilloonida indhaha iyo caabbinta kiimikaad, guud ahaan loo isticmaalo soo saarista heerka sare ee resin polyurethane aan midab lahayn).

30. Ujeedada wax ka beddelka MDI iyo hababka wax ka beddelka guud

A: Liquefied MDI: Ujeeddo la beddelay: MDI saafi ah oo dareere ah waa MDI wax laga beddelay oo dareere ah, taas oo ka gudubta cilladaha qaar ee MDI saafi ah (oo ku adag heerkulka qolka, dhalaalinta marka la isticmaalo, kuleyl badan ayaa saameeya waxqabadka), iyo sidoo kale waxay bixisaa saldhigga ballaaran. wax ka beddelka hagaajinta iyo hagaajinta waxqabadka maaddooyinka polyurethane ee ku salaysan MDI.

Hababka:

① urethane modified MDI dareere ah.

② karbodiimide iyo uretonimine oo la beddelay MDI dareere ah.

31. Waa maxay noocyada polyols-ka polymer ee sida badan loo isticmaalo?

A: Polyester polyol, polyeter polyol

32. Immisa habab wax soo saar warshadeed ayaa jira polyester polyols?

A: Habka dhalaalidda faakuumka B, habka gaaska sidaha dhalaalaysa, habka distillation azeotropic

33. Waa maxay qaababka gaarka ah ee ku yaala laf dhabarta molecular ee polyesterka iyo polyeterka?

A: Polyester polyol: Qalab makromolecular ah oo ka kooban koox ester ah oo ku taal laf dhabarta molecular iyo kooxda hydroxyl (-OH) ee kooxda dhamaadka. Polyether polyols: Polymers ama oligomers ka kooban ether bonds (-O-) iyo dhamaadka bands (-Oh) ama kooxaha amin (-NH2) ee qaab dhismeedka laf dhabarta ee molecule.

34. Maxay yihiin noocyada polyols-ka polyeter-ka iyadoo loo eegayo sifooyinkooda?

A: polyeter polyeter oo aad u firfircoon, meeris polyeter polyols, polyols polyether dib u ololaya, polyols polyeter heterocyclic modified, polytetrahydrofuran polyols.

35. Immisa nooc oo polyeter caadi ah ayaa jira marka loo eego wakiilka bilawga ah?

J: Polyoxide propylene glycol, polyoxide propylene triol, polyeter xumbo adag, polyether-ka aan saturation hoose.

36. Waa maxay faraqa u dhexeeya polyeterrada hydroxy-terminated iyo amine-terminated polyeter?

Polyeter-ka Aminoterminatedku waa polyoxide allyl ethers kaas oo dhamaadka hydroxyl lagu beddelo koox amin ah.

37. Waa maxay noocyada poliurethane kataliyat ee inta badan la isticmaalo? Waa kuwee noocyada inta badan la isticmaalo?

A: Amine kicinta sare, noocyada sida caadiga ah loo isticmaalo waa: triethylenediamine, dimethylethanolamine, n-methylmorpholine, N, n-dimethylcyclohexamine

Iskudhisyada alkyl ee biraha ah, noocyada sida caadiga ah loo isticmaalo waa: organotin katalysts, waxa loo qaybin karaa octoate stannous, stannous oleate, dibutyltin dilaurate.

38. Maxay yihiin fidiyeyaasha silsiladaha polyurethane ee caadi ahaan loo isticmaalo?

A: Polyols (1, 4-butanediol), aalkolada alicyclic, alkolada udugga, diamines, amines alkohol (ethanolamine, diethanolamine)

39. Habka falcelinta isocyanates

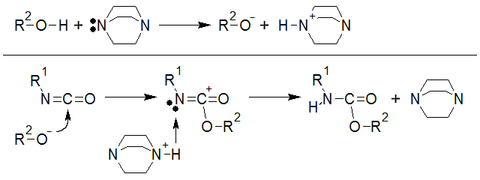

J: Dareen-celinta isocyyanates ee leh xeryahooda hydrogen ee firfircoon waxaa sababa xarunta nucleophilic ee molecule-ka firfircoon ee hydrogen oo weeraraya atamka carbon ku salaysan ee NCO. Habka falcelinta waa sida soo socota:

40. Sidee buu qaabka isocyanate u saameeyaa falcelinta kooxaha NCO?

A: Electronegativity ee kooxda AR: haddii kooxda R ay tahay koox nuugista elektarooniga ah, cufnaanta daruuriga elektarooniga ah ee atomka C ee kooxda -NCO ayaa ka hooseeya, waxayna aad ugu nugul tahay weerarka nucleophiles, taas oo ah, waa. Way fududahay in la sameeyo falcelinta nucleophilic leh aalkolada, amines iyo xeryahooda kale. Haddii R ay tahay koox ku-deeqaha elektarooniga ah oo lagu wareejiyo daruuraha elektarooniga ah, cufnaanta daruuriga elektaroonigga ah ee atomka C ee kooxda -NCO way kordhi doontaa, taasoo ka dhigaysa mid aan u nugulayn weerarka nucleophiles, iyo awooddeeda falcelinta ee xeryahooda hydrogen firfircoon hoos u dhac B. Saamaynta soo-jiidashada: Sababtoo ah diisocyanate aromatic waxay ka kooban tahay laba kooxood oo NCO ah, marka ugu horeysa -NCO hiddo-wadaha ka qaybqaata falcelinta, sababtoo ah saameynta isku-dhafka ah ee giraanta udgoonka, kooxda -NCO oo aan ka qayb qaadan falcelinta ayaa door ka ciyaari doonta doorka. ee kooxda nuugista elektarooniga ah, si ay dhaqdhaqaaqa falcelinta ee kooxda ugu horeysay ee NCO waa la wanaajiyey, taas oo ah saamaynta induction. C. saamaynta steric: In molecules diisocyanate udgoon, haddii laba -NCO kooxaha ku jira giraanta udgoon isku mar, markaas saamaynta hal koox NCO on falcelinta ee kooxda kale ee NCO inta badan waa mid aad u muhiim ah. Si kastaba ha noqotee, marka laba kooxood oo NCO ah ay ku yaalaan siddo udgoon oo kala duwan oo isku mid ah, ama ay kala soocaan silsiladaha hydrocarbon ama siddo udgoon, isdhexgalka iyaga ka dhexeeya waa mid yar, waxayna hoos u dhigtaa korodhka dhererka silsiladda hydrocarbon ama kororka tirada siddooyin caraf udgoon.

41. Noocyada xeryahooda hydrogen ee firfircoon iyo falcelinta NCO

A: Aliphatic NH2> Kooxda caraf udgoon Bozui OH>Biyaha> Secondary OH> Phenol OH> Kooxda Carboxyl> urea la beddelay> Amido> Carbamate. (Haddii cufnaanta daruuriga elektarooniga ah ee xarunta nucleophilic ay sare u kacdo, electronegativity ayaa sii xoogeysanaya, iyo falcelinta falcelinta isocyanate waa ka sarreeyaa xawaaraha falcelintuna waa dhakhso; Haddii kale, hawshu waa yar tahay.)

42. Saamaynta iskudhisyada hydroxyl ee falcelintooda isocyanates

A: Falcelinta ee xeryahooda hydrogen firfircoon (ROH ama RNH2) waxay la xiriirtaa sifooyinka R, marka R waa koox elektaroonig ah (electronegativity hoose), way adag tahay in lagu wareejiyo atamka hydrogen, iyo falcelinta ka dhexeeya xeryahooda hydrogen firfircoon iyo NCO aad ayey u adag tahay; Haddii R uu yahay beddelka ku-deeqaha elektarooniga ah, falcelinta xeryahooda hydrogen ee firfircoon ee NCO waa la wanaajin karaa.

43. Waa maxay isticmaalka falcelinta isocyanate ee biyaha

J: Waa mid ka mid ah falcelinta aasaasiga ah ee diyaarinta xumbo polyurethane. Dareen-celinta u dhaxaysa iyaga ayaa marka hore soo saarta karbomic acid aan xasilloonayn, ka dibna u jajabisa CO2 iyo amines, iyo haddii isocyyanate-ka xad-dhaafka ah, amiinka ka soo baxaa wuxuu la falgalaa isocyanate si uu u sameeyo urea.

44. Diyaarinta elastomer polyurethane, waxa ku jira polyols-ka biyaha ku jira waa in si adag loo xakameeyo.

J: Wax xumbo ah lagama rabo elastomers, dahaarka iyo fiilooyinka, markaa waxa ku jira biyaha ku jira alaabta ceeriin waa in si adag loo xakameeyo, inta badan wax ka yar 0.05%.

45. Farqiga u dhexeeya saamaynta catalytic ee amin iyo kicinta tin ee falcelinta isocyanate

J: Amine kiciyayaal sare waxay leeyihiin hufnaan sare oo firfircooni ah oo ku saabsan falcelinta isocyanate ee biyaha, halka kicinta tiintu ay leeyihiin waxtar sare oo firfircooni ah falcelinta isocyanate ee kooxda hydroxyl.

46. Waa maxay sababta resin polyurethane loo tixgelin karo inuu yahay polymer block ah, maxayse yihiin sifooyinka qaabka silsiladda?

Jawaab: Sababtoo ah qaybta silsiladda ee resin polyurethane waxay ka kooban tahay qaybo adag oo jilicsan, qaybta adag waxay loola jeedaa qaybta silsiladda ee ay samaysay falcelinta isocyanate, silsilad fidiyaha iyo crosslinker ee silsiladda ugu weyn ee molecules polyurethane, kooxahani waxay leeyihiin isku xirnaan weyn. tamarta, mugga booska weyn iyo qallafsanaan weyn. Qaybta jilicsani waxay tilmaamaysaa kaarboon-kaarboon silsiladda polymer polyol, kaas oo leh dabacsanaan wanaagsan oo ah qayb dabacsan oo ka mid ah silsiladda weyn ee poliurethane.

47. Maxay yihiin arrimaha saameeya sifooyinka alaabta poliurethane?

A: Tamar isku xidhka kooxda, bond hydrogen, crystallinity, degree crosslinking, miisaanka kelli, qayb adag, qayb jilicsan.

48. Waa maxay alaabta ceeriin waa qaybaha jilicsan iyo kuwa adag ee silsiladda ugu weyn ee alaabta polyurethane

J: Qaybta jilicsan waxay ka kooban tahay oligomer polyols (polyester, polyether diols, iwm.), iyo qaybta adag waxay ka kooban tahay polyisocyanates ama isku-darkooda oo leh silsilado yaryar oo silsilado molecule ah.

49. Sidee qaybaha jilicsan iyo qaybaha adag u saameeyaan sifooyinka alaabta poliurethane?

A: Qaybta jilicsan: (1) Miisaanka molecular ee qaybta jilicsan: iyada oo loo maleynayo in miisaanka molecular ee poliurethane uu la mid yahay, haddii qaybta jilicsani ay tahay polyester, xoogga polyurethane wuxuu kordhin doonaa korodhka miisaanka molecular ee diol polyester ah; Haddii qaybta jilicsani ay tahay polyeter, xoogga polyurethane ayaa hoos u dhacaya iyadoo la kordhinayo miisaanka molecular ee diol polyether, laakiin dhererku wuu kordhiyaa. (2) Karistalinnimada qaybta jilicsan: Waxay leedahay qayb weyn oo ku saabsan crystallinity ee qaybta silsiladda polyurethane ee toosan. Guud ahaan, crystallization waxay faa'iido u leedahay hagaajinta waxqabadka alaabta polyurethane, laakiin mararka qaarkood crystallization waxay yareysaa dabacsanaanta heerkulka hooseeya ee walxaha, iyo polymer-ka crystalline inta badan waa mugdi.

Qaybta adag: Qaybta silsiladda adag waxay badanaa saamaysaa jilicsanaanta iyo heerkulka dhalaalka iyo sifooyinka heerkulka sare ee polymerka. Polyurethanes oo ay diyaariyeen isocyyanates aromatic waxaa ku jira siddo udgoon oo adag, sidaas darteed xoogga polymer ee qaybta adag ayaa kor u kacda, xoogga maaddaduna guud ahaan way ka weyn tahay kan aliphatic isocyanate polyurethane, laakiin caabbinta hoos u dhaca ultraviolet waa mid liidata, wayna fududahay in jaalaha ah. Aliphatic polyurethane ma hurdi.

50. Kala soocida xumbo polyurethane

A: (1) xumbo adag iyo xumbo jilicsan, (2) cufnaanta sare iyo xumbo cufnaanta hoose, (3) nooca polyester-ka, nooca polyether-ka, (4) nooca TDI, nooca MDI, (5) xumbo polyurethane iyo xumbo polyisocyanurate, (6) Habka hal-tallaabo iyo wax-soo-saarka habka prepolymerization, habka joogtada ah iyo wax-soo-saarka joogtada ah, (8) xannibaadda xumbo iyo xumbo qaabaysan.

51. Dareen-celinta aasaasiga ah ee diyaarinta xumbo

J: Waxa loola jeedaa falcelinta -NCO oo leh -OH, -NH2 iyo H2O, iyo marka la falcelinayo polyols, "falcelinta jel" ee habka xumbo guud ahaan waxaa loola jeedaa falcelinta samaynta ee carbamate. Sababtoo ah alaabta ceeriin ee xumbo waxay isticmaashaa alaabooyin cayriin oo badan oo shaqeynaya, shabakad isku xiran ayaa la helayaa, taas oo u oggolaanaysa nidaamka xumbo si dhakhso ah.

Dareen-celinta xumbada waxay ku dhacdaa nidaamka xumbo-gelinta iyadoo ay jiraan biyo. Waxa loogu yeero "falcelinta xumbo-sameynta" guud ahaan waxaa loola jeedaa falcelinta biyaha iyo isocyanate si ay u soo saaraan urea beddelan oo ay sii daayaan CO2.

52. Habka nukliyeerka ee goobooyin

Walxaha ceeriin waxay ka falceliyaan dareeraha ama waxay ku xiran tahay heerkulka ay soo saarto falcelinta si ay u soo saarto walax gaas oo ay u beddesho gaaska. Iyadoo horumarka falcelinta iyo soo saarista qadar badan oo kulaylka falcelinta, qadarka walxaha gaaska iyo isbeddelka ayaa si joogto ah u kordhay. Marka fiirsashada gaasku ay korodho wixii ka baxsan fiirsashada dherjinta, xumbo joogto ah ayaa bilaaba inay ku samayso marxaladda xalka oo kor u kacda.

53. Doorka xasilinta xumbo ee diyaarinta xumbo polyurethane

A: Waxay leedahay saamaynta emulsification, si ay u milmay wadajirka ah ee u dhexeeya qaybaha walxaha xumbo waa la wanaajiyey; Ka dib marka lagu daro surfactant silicone, sababtoo ah waxay si weyn u yaraynaysaa xiisadda dusha sare ee γ dareeraha, tamarta bilaashka ah ee korodhka ah ee loo baahan yahay kala firdhinta gaaska ayaa la dhimay, sidaas darteed hawada ku kala firirsan alaabta ceeriin waxay u badan tahay inay nukleate inta lagu jiro habka isku dhafka, kaas oo waxay gacan ka geysataa soo saarista xumbo yaryar waxayna hagaajinaysaa xasilloonida xumbo.

54. Habka xasilloonida xumbo

J: Ku darida surfactants ku habboon waxay ku habboon tahay samaynta kala firdhinta xumbo wanaagsan.

55. Habka samaynta xumbo unug furan iyo xumbo unug xidhan

J: Habka samaynta xumbo-unug-furan: Inta badan, marka uu jiro cadaadis weyn oo xumbo ah, xoogga darbiga xumbo ee uu sameeyay falcelinta jel ma aha mid sare, iyo filimka derbiga ma u adkeysan karo fidinta sababay Cadaadiska gaaska ee kor u kaca, filimka gidaarka xumbo waa la jiidaa, gaaskuna wuxuu ka baxsadaa dillaaca, sameynta xumbo-unug furan.

Habka qaabeynta xumbo-unugyada xiran: Nidaamka xumbo adag, sababtoo ah falcelinta polyols-ka polyeter-ka ee leh miisaan badan oo shaqeynaya iyo miisaan yar oo leh polyisocyanate, xawaaraha jelku waa mid aad u dhakhso badan, gaaska ku jira xumbo ma jebin karo derbiga xumbo , sidaas darteed samaynta xumbo-unugyada xiran.

56. Habka xumbaynta ee wakiilka xumbo jirka iyo kiimikaad xumbo

J: Wakiilka afuufista jirka: Wakiilka afuufista jireed waa daloolada xumbo waxay ku sameysmeen isbeddelka qaabka jireed ee walax gaar ah, taas oo ah, iyada oo loo marayo ballaarinta gaaska ciriiriga ah, isbeddelka dareeraha ama kala dirida adkaha.

Kiimikooyinka afuufida: Kiimikada kiimikooyinka waa isku-dhisyo, marka kulaylku bakhtiyo, sii daaya gaasaska sida kaarboon laba ogsaydh iyo nitrogen oo sameeya daldaloolo fiican oo ka samaysan halabuurka polymer.

57. Habka diyaarinta ee xumbo poliurethane jilicsan

J: Habka hal-tallaabo iyo habka prepolymer

Habka Prepolymer: taas oo ah, polyether-ka iyo falcelinta TDI-da ee xad-dhaafka ah waxaa lagu sameeyaa prepolymer ka kooban koox NCO lacag la'aan ah, ka dibna lagu qaso biyo, kicin, xasiliye, iwm, si loo sameeyo xumbo. Habka hal-tallaabo: Qalab kala duwan oo cayriin ah ayaa si toos ah loogu dhex daraa madaxa isku dhafka iyada oo loo marayo xisaabinta, iyo tallaabo ayaa laga sameeyaa xumbo, taas oo loo qaybin karo mid joogto ah oo joogto ah.

58. Astaamaha xumbo toosan iyo xumbo toosan

Habka saxanka cadaadiska dheellitiran: waxaa lagu gartaa isticmaalka warqadda sare iyo saxanka daboolka sare. Habka jeexjeexa qulqulka: waxaa lagu gartaa isticmaalka jeexjeexa qulqulka iyo saxanka soo degista suunka qaada.

Sifooyinka xumbo toosan: waxaad isticmaali kartaa qulqul yar si aad u hesho aag weyn oo iskutallaabta ah ee blocks xumbo, oo badiyaa isticmaal mishiinka xumbo toosan si aad u hesho isla qaybta block, heerka socodka waa 3 ilaa 5 jeer ka weyn kan toosan. xumbo; Sababtoo ah qaybta weyn ee isku-dhafka ah ee xumbo-xumada, ma jiro maqaarka sare iyo kan hoose, iyo maqaarka cidhifku sidoo kale waa dhuuban, sidaas darteed luminta goynta ayaa si weyn loo dhimay. Qalabku wuxuu daboolayaa aag yar, dhererka geedku wuxuu ku saabsan yahay 12 ~ 13m, kharashka maalgashiga ee warshadda iyo qalabkuna wuu ka hooseeyaa habka xumbo-saarka jiifka ah; Way fududahay in la beddelo hopper iyo qaabka si loo soo saaro xumbo cylindrical ama leydi ah, gaar ahaan xashiishka xumbo wareega ee goynta wareega.

59. Qodobbada aasaasiga ah ee xulashada alaabta ceeriin ee diyaarinta xumbo jilicsan

A: Polyol: polyeter polyol ee xumbo block caadiga ah, miisaanka kelli guud ahaan waa 3000 ~ 4000, inta badan polyether triol. Triol Polyether oo leh miisaan kelli ah oo ah 4500 ~ 6000 ayaa loo isticmaalaa xumbo adkeysiga sare. Iyada oo korodhka miisaanka kellika ah, xoogga jilicsanaanta, dhererka iyo adkeysiga xumbo ayaa kordheysa. Dhaqdhaqaaqa polyeter-yada la midka ah ayaa hoos u dhacay. Kordhinta heerka shaqada ee polyeter-ka, fal-celinta ayaa si xad dhaaf ah loo dardargeliyay, heerka isdhaafsiga ee polyurethane ayaa kordhay, adkaanta xumbo waa la kordhiyaa, dhererka ayaa hoos u dhacaya. Isocyanate: Walxaha ceeriin ee isocyanate ee xumbada jilicsan ee polyurethane waa inta badan toluene diisocyanate (TDI-80). Dhaqdhaqaaqa yar ee TDI-65 waxaa kaliya loo isticmaalaa xumbo polyester polyester ama xumbo polieter gaar ah. Catalyst: Faa'iidooyinka xumbada jilicsan ee bulk jilicsan ayaa qiyaas ahaan loo qaybin karaa laba qaybood: mid waa xeryahooda organometallic, caprylate stannous ayaa ah tan ugu badan ee la isticmaalo; Nooc kale waa amines jaamacadeed, oo badanaa loo isticmaalo sida dimethylaminoethyl ethers. Xasijiye xumbo: Xumbo bulk polyester polyurethane, surfactants non-silicon ayaa inta badan la isticmaalaa, iyo xumbo bulk polyether, organosilica-oxidized olefin copolymer ayaa inta badan la isticmaalaa. Wakiilka xumbo: Guud ahaan, biyaha kaliya ayaa loo isticmaalaa sida wakiilka xumbo marka cufnaanta xumbada jilicsan ee polyurethane ay ka weyn tahay 21 kg halkii mitir cubic; Iskudhisyada dhibco karkaraya ee hooseeya sida methylene chloride (MC) ayaa loo isticmaalaa sidii wakiilada afuufista kaaliyaha ah oo keliya qaababka cufnaanta hoose.

60. Saamaynta xaaladaha deegaanka ee sifooyinka jireed ee xumbo-xidhka

J: Saamaynta heerkulka: falcelinta xumbo ee poliurethane waxay kordhisaa marka heerkulka maaddadu kordho, taas oo keeni doonta khatarta gubashada asaasiga ah iyo dabka ee qaababka xasaasiga ah. Saamaynta qoyaanka hawada: Iyadoo korodhka qoyaanka, ay sabab u tahay falcelinta kooxda isocyanate ee xumbo leh biyaha hawada, adkaanta xumbo ayaa hoos u dhacda iyo dhererka ayaa kordha. Xoogga xajinta ee xumbodu waxay kordhisaa korodhka kooxda urea. Saamaynta cadaadiska atmospheric: Isla qaacido isku mid ah, marka aad xumbaynayso meel sare, cufnaanta si weyn ayaa loo dhimay.

61. Farqiga ugu weyn ee u dhexeeya habka alaabta ceeriin ee loo isticmaalo xumbo jilicsan oo qabow iyo xumbo kulul oo kulul.

J: Walxaha ceeriin ee loo isticmaalo qaabaynta qaboojiyaha waxay leeyihiin falcelin sare, mana jirto baahi loo qabo kuleyl dibadeed inta lagu jiro daaweynta, ku tiirsanaanta kulaylka uu keeno nidaamka, falcelinta daweynta asal ahaan waxaa lagu dhameyn karaa waqti gaaban, iyo caaryada ayaa awood u leh. lagu sii daayo dhowr daqiiqo gudahood ka dib duritaanka alaabta ceeriin. Dhaqdhaqaaqa alaabta ceeriin ee xumbo qaabaynta kulul waa mid hooseeya, isku dhafka falcelinta waxay u baahan tahay in lagu kululeeyo caaryada ka dib marka lagu xumbo caaryada, iyo sheyga xumbo waa la sii deyn karaa ka dib marka uu si buuxda u bislaado kanaalka dubista.

62. Waa maxay sifooyinka xumbo jilicsan ee qabow-qabow marka la barbar dhigo xumbo-kulul-kulul

A: ① Habka wax soo saarka uma baahna kulayl dibadda ah, wuxuu badbaadin karaa kulayl badan; ② Isku-dhafka sag-sare ee sarreeya (saamiga burburka), waxqabadka raaxada wanaagsan; ③ Heerka dib u celinta sare; ④ Xumbo aan lahayn olol dib u celi waxay kaloo leedahay sifooyin dib-u-dhigis ololka qaarkood; ⑤ Wareegga wax soo saarka gaaban, wuxuu badbaadin karaa caaryada, wuxuu badbaadin karaa kharashka.

63. Astaamaha iyo isticmaalka xumbo jilicsan iyo xumbo adag siday u kala horreeyaan

A: Astaamaha xumbo jilicsan: Qaab dhismeedka unugga ee xumbo jilicsan ee polyurethane ayaa inta badan furan. Guud ahaan, waxay leedahay cufnaanta hoose, soo kabashada laastikada wanaagsan, nuugista codka, xajinta hawada, ilaalinta kulaylka iyo waxyaabo kale. Isticmaalka: Inta badan waxaa loo isticmaalaa alaabta guriga, alaabta barkinta, alaabta barkinta kursiga gaariga, noocyo kala duwan oo jilicsan oo jilicsan oo la dhejiyay qalabyo isku dhafan, warshadaha iyo xumbo jilicsan ee madaniga ah ayaa sidoo kale loo isticmaalaa alaabta shaandhada, alaabta dahaarka dhawaaqa, alaabta aan shoogga lahayn, alaabta qurxinta, alaabta baakadaha iyo agabka dahaarka kulaylka.

Astaamaha xumbo adag: xumbada poliurethane waxay leedahay miisaan fudud, xoog gaar ah oo sarreeya iyo xasilloonida cabbirka wanaagsan; Waxqabadka kuleylka kuleylka ee xumbada adag ee polyurethane ayaa ka sareysa. Xoog dhejis adag; Waxqabadka gabowga wanaagsan, nolosha adeegga adiabatic dheer; Isku darka falcelinta ayaa leh dareere wanaagsan waxayna si habsami leh u buuxin kartaa godka ama booska qaabka kakan. Maaddada ceeriin ee wax soo saarka xumbo adag ee polyurethane ayaa leh falcelin sare, waxay gaari kartaa daaweyn degdeg ah, waxayna gaari kartaa waxtarka sare iyo wax soo saarka ballaaran ee warshadda.

Isticmaala: Waxa loo isticmaalaa sida walxaha dahaarka talaajadaha, qaboojiyaha, weelasha qaboojiyaha, kaydinta qaboojiyaha, dhuumaha saliidda iyo dhuumaha biyaha kulul, gidaarka dhismaha iyo dahaadhka saqafka, boodhka sandwich, iwm.

64. Qodobbada muhiimka ah ee naqshadeynta caanaha xumbo adag

A: Polyols: polyeter polyols loo isticmaalo qaabaynta xumbo adag guud ahaan waa tamar sare, qiimaha hydroxyl sare (miisaanka kelliyada hoose) polypropylene oxide polyols; Isocyanate: Waqtigan xaadirka ah, isocyanate loo isticmaalo xumbo adag ayaa inta badan ah polymethylene polyphenyl polyisocyanate (guud ahaan loo yaqaan PAPI), taas oo ah, MDI cayriin iyo polymerized MDI; Walaxaha afuufaya:(1)Wakiilka afuufaya CFC (2) HCFC iyo HFC (3) wakiilka afuufaya pentane (4) biyo; Xasijiye xumbo: Xasijiye xumbo loo isticmaalo qaabaynta xumbo adag ee polyurethane waa guud ahaan polymer block of polydimethylsiloxane iyo polyoxolefin. Waqtigan xaadirka ah, badi xasiliyeyaasha xumbo waa inta badan nooca Si-C; Catalyst: Kataliyatiyaha samaynta xumbo adag ayaa inta badan ah amine jaamacadeed, iyo kicinta organotin waxa loo isticmaali karaa waqtiyo gaar ah; Waxyaabaha kale ee lagu daro: Marka loo eego shuruudaha iyo baahiyaha isticmaalka kala duwan ee alaabta xumbo adag ee poliurethane, ololka ololka, wakiilada furitaanka, qiiqa joojiyaha, wakiilada gabowga, wakiilada caarada, wakiilada adag iyo waxyaabo kale ayaa lagu dari karaa caanaha.

65. Mabda'a diyaarinta xumbo samaynta maqaarka oo dhan

J: Xumbo maqaarka isku xidha (ISF), oo sidoo kale loo yaqaano xumbo maqaar-is-maqaar ah, waa xumbo caag ah oo soo saarta maqaarkeeda cufan wakhtiga wax soo saarka.

66. Astaamaha iyo isticmaalka elastomers-ka microporous polyurethane

A: Astaamaha: elastomer polyurethane waa polymer block ah, guud ahaan ka kooban oligomer polyol dabacsan silsilad dheer oo jilicsan qayb jilicsan, diisocyanate iyo silsilad fidiyaha si ay u sameeyaan qayb adag, qayb adag iyo qayb jilicsan habayn beddelka, samaynta unug qaab-dhismeedka soo noqnoqda. Marka lagu daro ka kooban kooxaha ammonia ester, polyurethane waxay samayn kartaa curaarta hydrogen gudaha iyo inta u dhaxaysa molecules, iyo qaybaha jilicsan iyo kuwa adag waxay samayn karaan gobollada microphase waxayna soo saari karaan kala soocida microphase.

67. Maxay yihiin sifooyinka waxqabadka ugu muhiimsan ee elastomers polyurethane

A: Tilmaamaha waxqabadka: 1, xoogga sare iyo dabacsanaanta, waxay noqon kartaa mid aad u ballaaran oo adag (Shaw A10 ~ Shaw D75) si loo ilaaliyo dabacsanaanta sare; Guud ahaan, qallafsanaanta hoose ee loo baahan yahay waxaa lagu gaari karaa iyada oo aan balaastig lahayn, markaa ma jirto wax dhibaato ah oo ay keento socdaalka balaastikada; 2, oo ku hoos adkaanta isla, awood qaadis ka sarraysa marka loo eego elastomeryada kale; 3, iska caabin aad u fiican, caabbinta xirashada waa 2 ilaa 10 jeer ka caag dabiici ah; 4. Saliid aad u fiican iyo caabbinta kiimikada; U adkaysta shucaaca poliurethane ee caraf udgoon; Iska caabbinta oksijiin heer sare ah iyo iska caabin ozone; 5, iska caabin saameyn sare leh, iska caabin daal wanaagsan iyo iska caabin naxdin leh, oo ku habboon codsiyada dabacsanaanta-soo noqnoqda; 6, dabacsanaanta heerkulka hooseeya ayaa wanaagsan; 7, polyurethane caadiga ah looma isticmaali karo in ka badan 100 ℃, laakiin isticmaalka caanaha gaarka ah waxay u adkeysan kartaa heerkulka sare ee 140 ℃; 8, kharashyada naqshadaynta iyo habaynta ayaa aad u hooseeya.

68. Elastomers Polyurethane waxaa loo kala saaraa si waafaqsan polyols, isocyyanates, hababka wax soo saarka, iwm.

A: 1. Marka loo eego alaabta ceeriin ee oligomer polyol, polyurethane elastomers waxaa loo qaybin karaa nooca polyester, nooca polyether, nooca polyolefin, nooca polycarbonate, iwm. 2. Marka loo eego kala duwanaanshaha diisocyanate, waxa loo qaybin karaa aliphatic iyo elastomer caraf udgoon, waxaana loo qaybiyaa nooca TDI, nooca MDI, nooca IPDI, nooca NDI iyo noocyo kale; Laga soo bilaabo habka wax soo saarka, elastomers polyurethane ayaa dhaqan ahaan loo qaybiyaa saddex qaybood: nooca shubista (CPU), thermoplasticity (TPU) iyo nooca isku dhafka (MPU).

69. Maxay yihiin arrimaha saameeya sifooyinka elastomer-yada poliurethane marka loo eego qaab dhismeedka molecular?

A: Marka laga eego aragtida qaabdhismeedka molecular, elastomer polyurethane waa polymer block, guud ahaan ka kooban oligomer polyols dabacsan silsilad dheer oo jilicsan, diisocyanate iyo silsilad fidsan si ay u sameeyaan qayb adag, qayb adag iyo qayb jilicsan oo beddelaad ah, samaynta soo noqnoqda unug dhismeed. Marka lagu daro ka kooban kooxaha ammonia ester, polyurethane waxay samayn kartaa curaarta hydrogen gudaha iyo inta u dhaxaysa molecules, iyo qaybaha jilicsan iyo kuwa adag waxay samayn karaan gobollada microphase waxayna soo saari karaan kala soocida microphase. Sifooyinkan qaab-dhismeedku waxa ay ka dhigayaan elastomer-yada poliurethane in ay leeyihiin iska caabin aad u fiican iyo adayg, oo loo yaqaan "caag u adkaysta xidhashada".

70. Farqiga wax qabad ee u dhexeeya nooca polyester-ka caadiga ah iyo elastomer-yada nooca ether-ka ah

J: Unugyada Polyester-ka waxaa ku jira kooxo badan oo ester ah (-COO-), kuwaas oo samayn kara curaarta hydrogen intramolecular xoog leh, sidaas darteed polyester polyurethane wuxuu leeyahay awood sare, xirto caabbinta iyo caabbinta saliidda.

elastomer-ka laga diyaariyey polyols-ka polyeter-ka wuxuu leeyahay xasillooni hydrolysis wanaagsan, caabbinta cimilada, dabacsanaanta heerkulka hooseeya iyo caabbinta caaryada. Isha maqaalka/Barashada Polymer Research

Waqtiga boostada: Jan-17-2024